The Science Behind Stainless Steel: Why It’s the Ideal Material for Modern Kitchens

- Share

- publisher

- Samsink

- Issue Time

- Oct 23,2025

Summary

Stainless steel shines in modern kitchens, blending trendiness with science-backed perks. It’s an alloy mainly of iron, plus chromium, nickel (boosts flexibility/shine), molybdenum (fights chloride corrosion), etc.

Its kitchen strengths: 1. Durable—resists impacts, scratches, high heat . 2. Rust-proof—handles humidity, acids (citrus/vinegar) and cleaners. 3. Hygienic—non-porous, no bacteria/mold, easy to disinfect. 4. Versatile—polished/brushed/matte finishes match any design.

Walk into any top restaurant or family home kitchen, and stainless steel steals the show—on countertops, sinks, and appliances. It’s not just trendy; its durability, rust resistance, and safety come from real science. Let’s break down why this material is a kitchen workhorse, with simple explanations and real-scene photos to make the science stick.

Understanding the Composition of Stainless Steel

The Alloys That Define Stainless Steel

At its core, stainless steel is an alloy primarily composed of iron (Fe), with chromium (Cr) being the critical element that imparts its renowned corrosion resistance. Typically, chromium content ranges from 10.5% to 20%, forming a passive oxide layer that shields the metal from environmental damage.

Other elements often added include:

-Nickel (Ni): Enhances ductility, corrosion resistance, and shine.

-Molybdenum (Mo): Improves resistance to chlorides and pitting corrosion.

-Titanium (Ti): Stabilizes the alloy, especially in high-temperature environments.

-Nitrogen (N): Increases strength and corrosion resistance.

-Figure 1: Typical composition of stainless steel alloys

| Element | Typical Range | Function |

| Iron (Fe) | Balance | Base metal providing strength |

Chromium (Cr) | 10.5–20% | Corrosion resistance via oxide layer formation |

Nickel (Ni) | 8–10% | Ductility, toughness, corrosion resistance |

| Molybdenum (Mo) | 0.2–3% | Pitting and crevice corrosion resistance |

| Other Elements | Trace | Specific properties enhancement |

The Role of the Chromium Oxide Layer

The defining characteristic of stainless steel is the formation of a thin, invisible chromium oxide (Cr₂O₃) layer on its surface when exposed to oxygen. This passive film is self-healing—if scratched or damaged, it reforms automatically, maintaining the material’s corrosion resistance.

Why Stainless Steel Is the Optimal Choice for Kitchen Environments

1. Superior Durability and Structural Integrity

Stainless steel is notably resistant to impacts, scratches, and high temperatures. Its tensile strength ensures that kitchen fixtures, appliances, and countertops can withstand daily wear and tear without warping or cracking.

-Impact resistance minimizes dents from heavy objects.

-High-temperature resilience allows for cooking directly on surfaces or near heat sources.

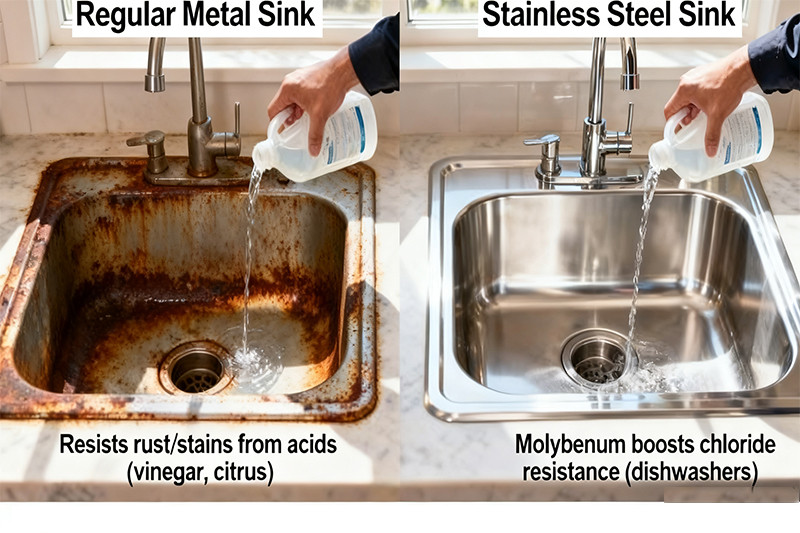

2. Exceptional Corrosion and Rust Resistance

Kitchen environments are humid and expose surfaces to water, acids, and cleaning agents. Stainless steel's corrosion resistance ensures it remains pristine over years of use.

-Resistance to rust and staining even in the presence of acidic foods like citrus or vinegar.

-Molybdenum-enhanced alloys provide additional protection against chloride-induced corrosion—common in dishwashers and sink areas.

3. Hygienic and Food-Safe Surface

Stainless steel is non-porous, meaning it does not harbor bacteria or mold, making it ideal for food preparation.

-Easy to clean with standard disinfectants.

-Does not absorb odors or stains.

-Meets health and safety standards for food contact surfaces.

4. Aesthetic Versatility and Modern Appeal

The bright, reflective surface of stainless steel adds a sleek, contemporary look to any kitchen. Its color and finish can be customized—polished, brushed, or matte—to complement various design themes.

-Reflective surfaces enhance lighting.

-Color consistency ensures uniformity across appliances and fixtures.

-Compatible with other materials such as glass, wood, and tile.

Scientific Advantages of Stainless Steel in Kitchen Applications

1. Resistance to Heat and Thermal Stability

Stainless steel can withstand extreme temperatures without losing strength or warping. Its thermal conductivity allows for efficient heat distribution in cookware, while its high melting point (~1400°C) ensures durability in oven environments.

-Impact on cookware: Provides even cooking and resistance to warping.

-Impact on appliances: Maintains structural integrity under high heat.

2. Easy Maintenance and Chemical Resistance

The passive oxide layer not only resists corrosion but also resists chemical attack from cleaning agents like bleach, acids, and alkalis. This chemical inertness ensures long-term appearance and functionality.

-Stainless steel surfaces can be cleaned with abrasive scrubbers or chemical cleaners without damage.

-Resistance to staining reduces the need for frequent replacements.

3. Environmental Sustainability

Stainless steel is 100% recyclable with no loss of quality. Its long lifespan reduces the need for replacements, and recycling contributes to sustainable building practices.

-Recycling rate exceeds 80% in many regions.

-Use of eco-friendly manufacturing methods further enhances its sustainability profile.

Types of Stainless Steel Commonly Used in Kitchens

| Type | Composition | Typical Uses | Advantages |

| 304 (18/8) | 18% Cr, 8% Ni | Countertops, sinks, appliances | Corrosion-resistant, easy to clean |

| 316 | 16% Cr, 10% Ni, 2% Mo | Commercial kitchens, outdoor applications | Superior corrosion resistance, saltwater resistant |

| 430 | 16–18% Cr | Decorative fixtures, appliances | Cost-effective, magnetic |

Installation and Maintenance Tips for Longevity

-Regular cleaning with mild soap and water preserves the surface.

-Avoid abrasive cleaners that may scratch the surface.

-Use non-metallic scrubbers for stubborn stains.

-Address scratches promptly to maintain the passive layer.

-Polish surfaces periodically to retain shine.

Conclusion: The Scientific Edge of Stainless Steel in Kitchens

The scientific composition and unique properties of stainless steel make it indispensable in the culinary world. Its corrosion resistance, thermal stability, hygienic surface, and aesthetic appeal collectively contribute to its status as the ideal material for kitchens worldwide. As we continue to prioritize durability, safety, and sustainability, stainless steel remains at the forefront, merging science with design to create functional, beautiful, and long-lasting culinary spaces.

This comprehensive exploration underscores why stainless steel is not merely a popular choice but a scientifically superior material for kitchen environments. Its robustness, hygiene, and visual appeal ensure it remains the benchmark for quality and innovation in culinary spaces.